Originally, adjustment would only happen after 28 days. Now, the webapp gives the managers more time to react to operational changes accordingly.

Republic Cement teamed up with Aboitiz Data Innovation (ADI) on a project that forms a significant part of the thrust to improve business operations, curb carbon emissions, and increase efficiency. The two Aboitiz Group business units collaborated on the 28-Day Strength Prediction Tool that predicts cement quality based on historical data and uses data science and artificial intelligence (DSAI) solutions to optimize the cement manufacturing process. The AI tool also drastically decreases carbon emissions while ensuring customer requirements are met — a first in the Philippine cement industry.

The DSAI application has proven to be especially helpful to Republic Cement’s Production and Quality teams, allowing them to optimize the blend of raw materials in the cement mix by instantly harnessing complex algorithms, thus saving time and resources. The development of the product also led to innovative data-driven adjustments that allowed the company to embed the tool as part of daily operations.

“Quality Managers are more confident in adjusting their metrics in improving product quality. Originally, adjustment would only happen after 28 days. Now, the webapp gives the managers more time to react to operational changes accordingly,” shared Rachelle Mindo, Republic Cement Quality Manager who is among the project’s end-users.

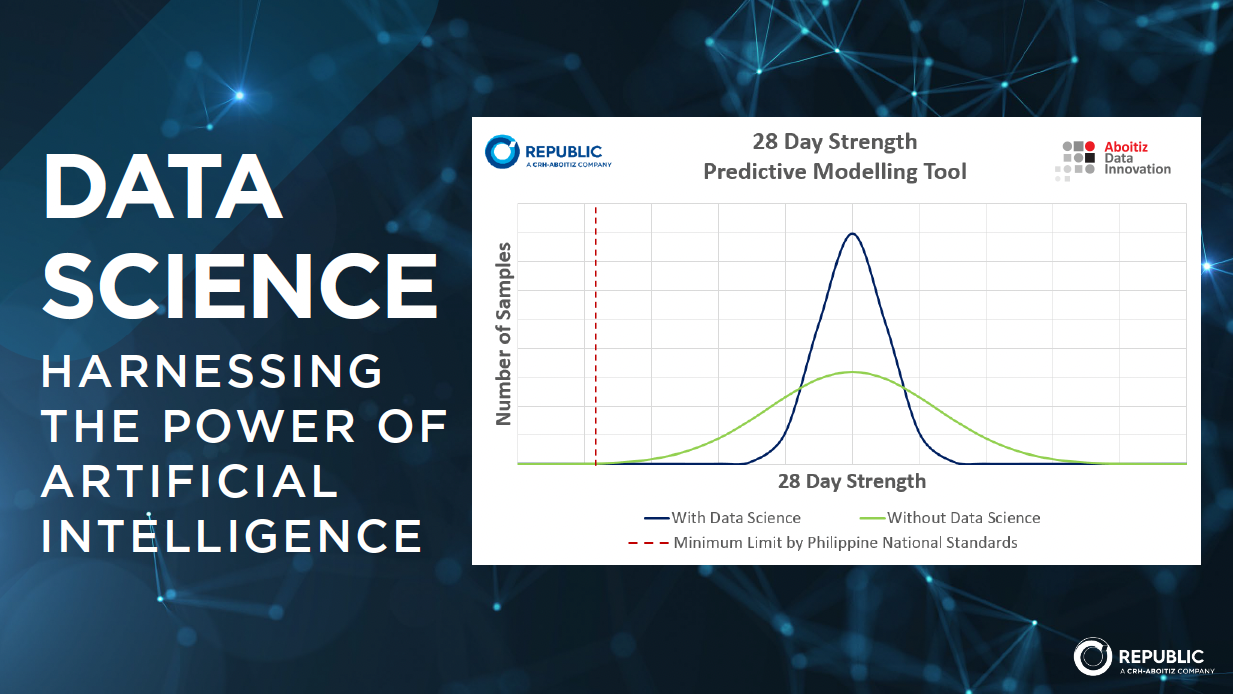

This product quality improvement is particularly evident in how the cement product consistently exceeds the strength requirements of Philippine National Standards. Through the AI tool, customers are assured of the cement’s strength right upon production.

By being able to optimize the cement manufacturing process through data science, Republic Cement is able to better manage its resources and increase efficiency of use when it comes to raw materials. This will also lead to more sustainable operations in the long-run.

–Nabil Francis, President and CEO, Republic Cement

The first site implementation was in July 2020 and, since then, ADI has successfully completed rollouts of the data science solutions in four out of six Republic Cement manufacturing plants. The project is on track for full rollout by the end of the year.

The AI tool also builds on Republic Cement’s work towards reducing CO2 emissions through manufacturing greener cement. Its accurate prediction of 28-day cement strength optimizes the manufacturing process even more through better resource management coupled with increased efficiency of raw materials used in cement production. Through this, the company achieves an additional reduction of 35,000 tons of CO2 emissions annually.

“Going forward, we envision data science as a key differentiator in driving digital transformation,” said Aboitiz Data Innovation Managing Director Dr. David R. Hardoon. “This use case of data science is a perfect example of synergies between the different subsidiaries of the Aboitiz Group. In working with Republic Cement, we are able to demonstrate exactly how Data Science can empower an organization to achieve business value while achieving measurable goals.”

As the DSAI governance center of the Aboitiz Group, ADI is responsible for the capacity building of DSAI capabilities across the businesses through demonstration, awareness, enablement, and ecosystem partnership contracting. Over the long term, the data science unit aims to roll out external DSAI products and services to prospective partners in search of innovative solutions.

“Even as the newest company under the Aboitiz Group, ADI is just as committed to fulfilling our brand promise of advancing business and communities through the power of data science. We will explore new possibilities, create greater impact, and deliver value for our stakeholders,” David affirms.