The current reality of the world is that almost everyone is collecting data. Bankers, retailers, manufacturers, even the government is keen on getting their hands on data, the new oil in the era of digitization. The idea of harnessing data to achieve a higher level of service and to optimize production processes has now become more of a necessity than a luxury. The first step being done by most industries nowadays is to collect huge amounts of data. However, the true value lies in extracting the relevant and important information that would aid in developing innovation, improving customer service, and differentiating from competition — all of which are crucial in growing any business. But when we get a hold of our data, the next question is: what now?

Data science, the practice of detecting patterns in data that would otherwise not make sense to some, the key to understanding how our customers behave, the tool to help us innovate our products and optimize our costs, is the answer to our “what now?” Applications of such have even grown throughout the years and across industries. Data science is utilized to detect the early onset of cancer in patients using image processing in the medical field. The e-commerce industry has been more efficient in providing relevant products for their customers using customer intelligence via digital footprints. The banking industry is much smarter in detecting fraud based on historical behavior. These and all other opportunities are the reason why data science and AI has grown to the extent that it becomes a necessity for any business. In the context of Republic Cement, the cement manufacturing arm of the Aboitiz Group, data science posed the promise of innovation in operations planning and optimization of production costs. The precision that data science will provide is especially important as there are plenty of factors in the manufacturing process that could potentially affect the quality of cement.

Portland cement, a complex product obtained from unprocessed natural materials: limestone and clay (P.C. Aïtcin, 2016), is the main product of Republic Cement. Due to its sensitive nature to minimal changes in chemical concentrations, both the Philippine government and industry set minimum standards for cement quality hence the need for constant adjustment of parameters to meet industry standards of cement strength. To address these concerns, the company teamed up with the UnionBank Data Solutions Team to create a solution which predicts cement quality based on the results of various historical chemical concentration combinations.

The project aims to produce AI-enabled data applications for all Republic Cement’s cement manufacturing plants. This endeavor will not only provide Republic data-driven insights but also allows Republic to remain steadfast in its commitment of delivering consistent and high-quality products for the Philippine concrete market.

In the context of Republic Cement…[t]he precision that data science will provide is especially important as there are plenty of factors in the manufacturing process that could potentially affect the quality of cement.

Business Challenge

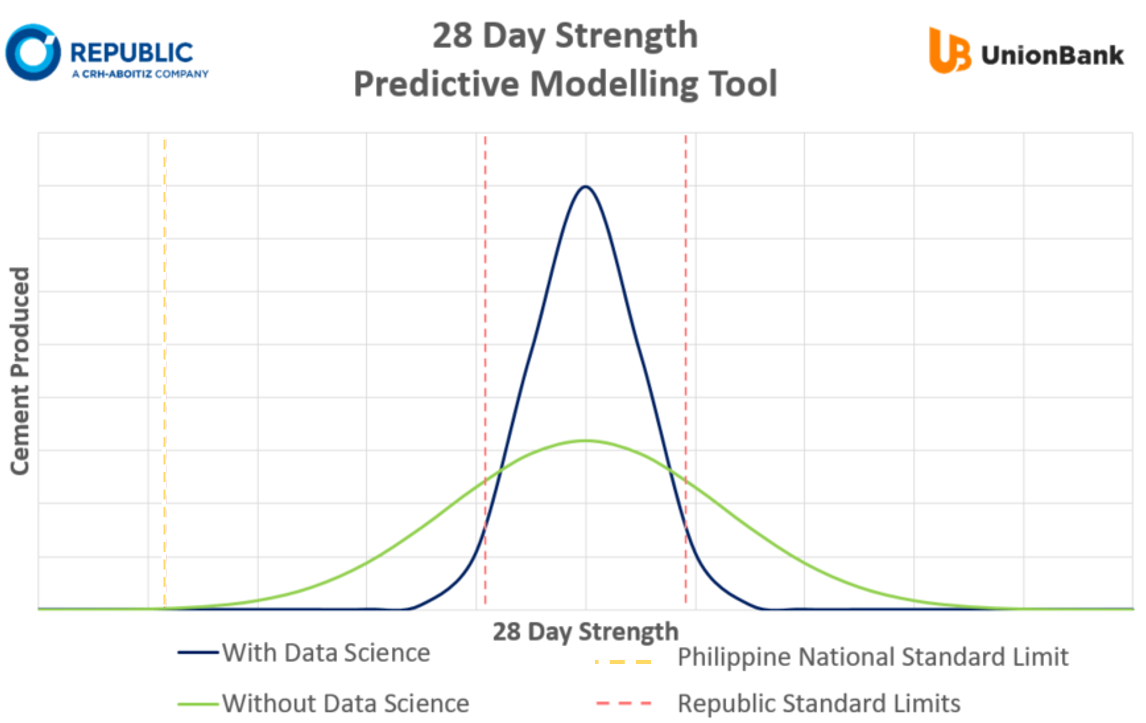

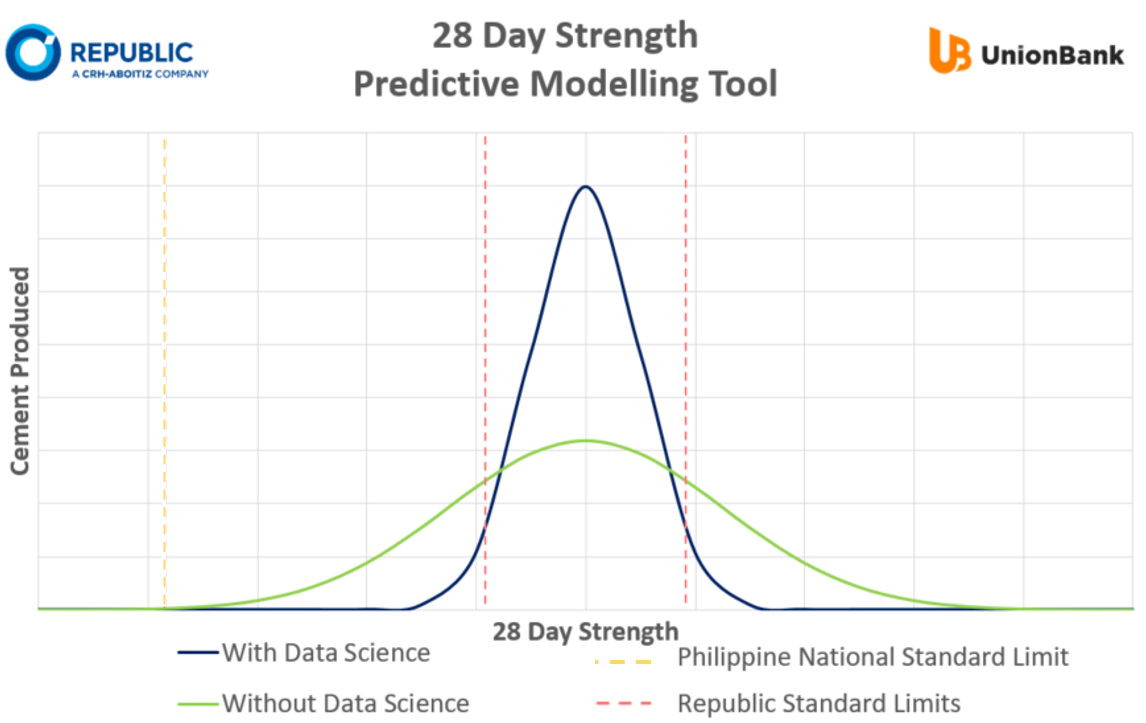

Republic’s challenge is how to organize years of historical data into information ready for decision-making in order to further optimize its operations. The main measure of success for Portland Cement is the measure of its 28-day strength, which indicates the quality, consistency, overall strength, and longevity of the cement. By being able to optimize the process further, Republic would be able to better manage its resources and increase efficiency of use when it comes to raw materials. This also would also lead to more sustainable operations in the long-run.

To begin working towards this, Republic Cement has put in place data infrastructures to collect relevant data about the various states and chemical compounds present in cement across the whole manufacturing process and identifying its quality after curing for 28 days. Further to just collecting and digitizing Republic’s data, there also needed to be a clear way to process this data into relevant information. Up until a year ago, the data was simply sitting in a database with little to no role in decisions that affect the results of 28-day strength testing, which largely relied on reactive decisions based on test results. In other words, Republic posed the question, “After having collected our data, what now?”

Potential consequences of not having this data support the cement manufacturing process is the inefficient use of raw materials (and thereby increased costs) in order to ensure that the cement meets both the Philippine National Standards on 28-day Strength as well as Republic’s own more stringent quality standards.

By being able to optimize the process further, Republic would be able to better manage its resources and increase efficiency of use when it comes to raw materials. This also would also lead to more sustainable operations in the long-run.

Solution

In exploring how to turn its data to relevant information, Republic Cement teamed up with the Aboitiz Data Science and AI Solutions Group to build an AI tool for its cement manufacturing operations. The product is designed as a data science application to help operators and quality managers optimize concentrations of raw ingredients in the cement mix by instantly harnessing complex algorithms, saving time and resources for the users. The development of the product also led to innovative data-driven adjustments making it important for the company to embed the tool as part of their daily operations planning.

Tests on the first version of the prediction tool have yielded promising results for Republic’s Teresa Plant. Republic encouraged quality managers to expand the product to other plants and utilize other sources of data as well. As of 2020, two manufacturing plants are now utilizing the AI tool as part of the overall process strategy. Improvements on the first deployment are also underway while expansion to other plants are being planned accordingly as well.

Lastly, being true to the value of innovation, the teams are looking into expanding the applications of data science and AI across the departments of Republic by exploring opportunities that venture into use cases of energy efficiency intelligence, cement sales forecasting, asset preventive maintenance, and many more. Indeed, something that would further promote an innovation and data-driven culture in the Republic Cement and the Aboitiz Group.

As of 2020, two manufacturing plants are now utilizing the AI tool as part of the overall process strategy. Improvements on the first deployment are also underway while expansion to other plants are being planned accordingly as well.